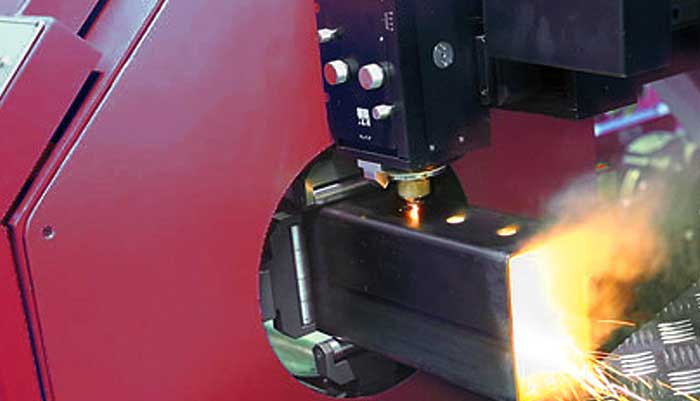

Square Tube

Fiber lasers are practically maintenance-free and have superior wall plug efficiency to CO2 laser cutters. They can also cut reflective materials and provide precise cutting. They can also be used to cut certain metal thicknesses faster than CO2 machines. Speed is relative when it involves cutting tube. It is possible to reduce the time required for tube processing and produce finished parts faster.

The fiber laser's small modules, which are compact and easily transportable, allow for redundancy. The resonator won't completely shut down if one module experiences a problem. In order to provide power for the down module, the fiber laser can temporarily produce more power until it is repaired. This can, of course, be done in the field. Sometimes, the fiber resonator will continue to produce reduced power until repairs are made. If a CO2 reactor has an issue, it can cause the whole resonator to go down.